Challenge:

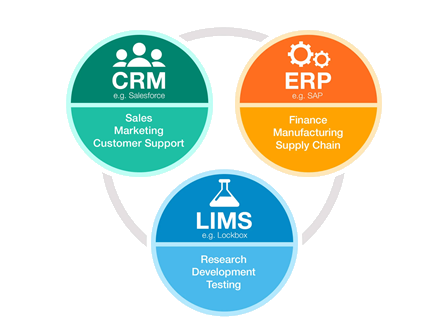

Perhaps the best motivation to interface your instruments to your LIMS is the expansion in lab profitability and researcher viability. Eliminating the manual entering of data and saves a huge load of time and exertion. Another vital motivation to interface your instruments to LIMS is the increment in information quality and uprightness that it yields. By eliminating the "human component" from the information move and passage condition, an immense wellspring of mistake is taken out.

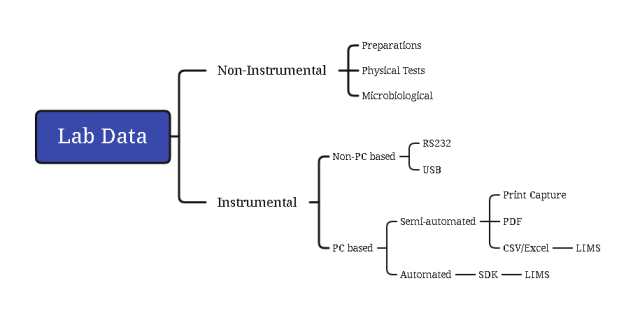

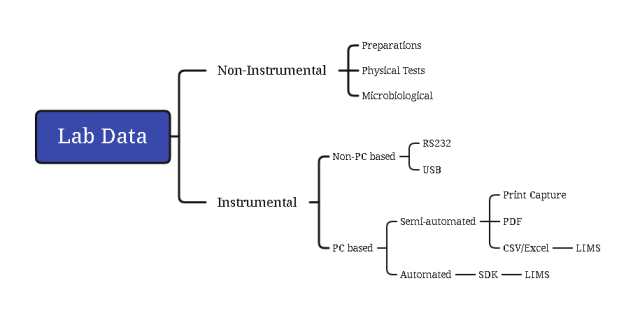

Unfortunately, Instruments vary in the ways in which instrument data is obtained. Therefore the optimal instrument interface is dependent on your compliance requirements, the instrument, the integration outcomes, and the amount of effort to expend. Interface selection criteria depend on security, integration, setup and extraction of data. The aim of the protocol is to maintain the connection and the integration between lap instruments and Silver-LIMS solution, and it is offering two ways of implementation according to the customer requirements